DDP’s proprietary NR Technology permits the rotation of two circular components, i.e. a beta flange and the canister, relative to each other. The NR Technology permits a full 360 rotation, with minor turning resistance, while maintaining a leak tight seal.

- DDP’s NR Technology features an innovative alpha or beta flange to allow full rotation of two components while maintaining a leak tight seal

- NR Technology utilizes a system of ball bearings and a custom molded Dynamic Seal to retain the integrity of the sealing faces.

- NR Technology can be customized to interface with all sizes of industry standard RTP ports

- The NR Technology fills in the gaps of standard docking processes. There is no need to be concerned with your contents being damaged by the rotation of the canister while docking.

Download Presentation

Download Presentation

Primary Purpose of NR Technology

DDP’s proprietary NR Technology permits the rotation of two circular components, i.e. a beta flange and the canister, relative to each other. The NR Technology permits a full 360 rotation, with minor turning resistance, while maintaining a leak tight seal.

Basic Principles of NR Technology

The NR technology is based on two independent but critical factors: the precise alignment between the two circular components and the dynamic seal that creates an air tight connection and still permits relative rotation.

The precise alignment in both the axial and the radial directions is achieved by a ball bearing system built right into the components of the NR Flange. These components are machined with extremely high precision to achieve the necessary tightness and performance.

The dynamic seal consists of a precision machined Teflon ring preloaded by a custom, molded silicone rubber compression seal.

The principles behind the NR Technology are solid. The NR Technology has been successfully implemented in numerous products, as described below.

Advantages & Applications

The most common RTP transfer port used in isolator installations is the one that requires rotation of the beta flange relative to the alpha flange. This rotation can be a problem when the components to be transferred need be oriented in a certain way and are not allowed to tumble.

The NR Technology resolves this basic conceptual problem with the RTP transfer technology by simply rotating the beta flange itself while allowing the body connected to the flange to remain stationary.

Below are some products that have successfully implemented the NR Technology.

NR Technology Based DDP Products

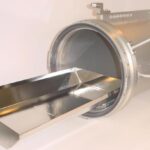

NRC Canister

NRC Canister

The NRC Canister is the most basic and proven of all applications. RTP canisters are used to transfer components into and out of isolator. If the components to be transferred cannot be allowed to tumble, the answer is the implementation of the NRC Canister.

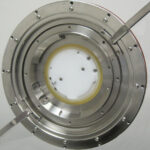

Alpha NR / NRF

Some docking applications require the beta flange to be stationary. One such application might be the connection of a beta flange of a tank to the alpha flange of an isolator. The Alpha NR/NRF system adopts the NR Technology to permit rotation of the alpha flange relative to the tank.

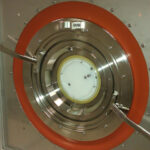

Beta NR-HP

Other applications require docking a beta flange mounted on a tank to the alpha flange that is solidly mounted onto the isolator. To allow this connection to be made, the NR Technology has been adopted in the Beta NR-HP flange that permits rotation of the beta flange relative to the tank with the added feature of permitting high pressure sealing of the flange for steam sterilization of the internal volume of the tank.

Photo Gallery

Related Products

The RTP Canister for the more challenging applications. With our patented NR Technology, the beta is free to rotate relative the canister body.

The Alpha port that is free to rotate during the docking process. Permits docking to a beta flange that is stationary and therefore cannot rotate.

The beta flange that is free to rotate during the docking process. Simplifies the docking of a fixed system, such as a tank, to an alpha flange that is stationary.