GIT-P2

An economic solution to Glove Integrity Testing

Home > Products > Glove Integrity Testers > GIT-P2

- Single channel glove testing

- Positive or negative pressure testing

- Self-contained, compact table top design

- Color touchscreen operator interface

- Printing functionality

- Programmable parameters

Download presentation

Download presentation

System Description

The GIT-P2 glove integrity tester is a state-of-the-art, economic, glove leak testing system for testing the integrity of glove/sleeves or gauntlets of isolator/RABS systems. The GIT-P2 is capable of simultaneously testing two gloves under positive or negative pressure.

The GIT-P2 glove integrity tester consists of a clean room compatible control console that the operator places in proximity to the gloveports to be tested and a set of appropriate glove interface devices that are specifically designed to interface with the glove system to be tested.

The GIT-P2 system is available in either a positive or negative pressure mode of operation depending on whether the glove system to be tested is part of an aseptic or a containment application. The test outcome of each glove tested is provided to the operator in the form of a Pass/Fail visual indicator and pressure values. If desired, test results can be printed for permanent record keeping.

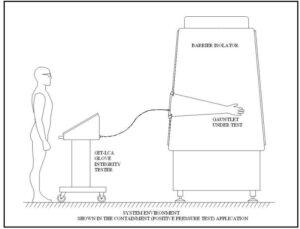

System Environment

Typical aseptic system installation, shown with glove/cuff type of test part interface and negative pressure test mode for aseptic filling operations. The glove under test is placed inside a vacuum chamber via a leak tight connection at the cuff.

For containment applications, the glove/sleeve are tested while oriented inside the isolator chamber.

|  |

Features

- Simple operation, validation and maintenance.

- Single channel glove testing

- Capable of testing single piece gauntlet or individual glove.

- Numeric feedback of tested item performance.

- Clear Pass/Fail test outcome feedback to the operator for each test channel.

- Print out of test result, parameters.

- Compact, portable table top design, can fit easily onto a cart or can be ordered

- with a clean room compatible cart.

- Slanted control panel, easily viewed and accessed.

- An economic glove testing solution.

Specifications

- Console width: 400mm / 15.75 inch.

- Console length: 400mm / 15.75 inch.

- Console Height: 220 mm / 8.7 inch.

- Material of construction: Stainless steel.

- Rugged construction.

- 12 foot long power cord.

- Retractable pneumatic connections to the gloveport interface hardware.

- Internal compressed air supply.

- Input power: 115VAC, 60hz / 220 VAC/50hz.

- Single channel operation

- CE Certified

Mode of Operation Options

Non-Sterile/Containment leak test (containment applications)

- Glove/Sleeve is pressurized from outside the isolator.

- In the event of a leak in the test item, positive pressure inside the test item causes airflow into the isolator system.

Sterile system leak test (aseptic applications)

- Glove/Sleeve placed under vacuum from outside the isolator.

- In the event of a leak in the test item, negative pressure outside the test item causes airflow out of the isolator system.

Gloveport Interface Hardware

The system connects to the test item by means of a gloveport interface device. A number of interface configurations are possible, depending on the application, mode of operation and gloveport manufacturer. Following are the basic categories of interface devices possible and diagrams that demonstrate the concept of each. (Click on link to view diagram)

Positive pressure/Containment applications

- Glove only interface, connection made at the cuff.

- Glove and sleeve interface, connection made at the cuff at the gloveport rim.

- Single piece gauntlet, connection made at thet gloveport rim.

Negative pressure/Aseptic applications

Documentation

Each system is shipped with an operator and maintenance manual that includes the following sections:

- Handling and transport

- System set up for operation

- System detailed description and operational instructions

- Maintenance instructions

- Validation support documentation such as Equipment, Functional and Design specification documents.

- Executed Functional Test Protocol

- List of recommended spare parts for two years of operation

- Manufacturer’s catalog cuts and instruction sheets for all commercial components.

- Electrical, mechanical, P&ID’s and assembly drawings

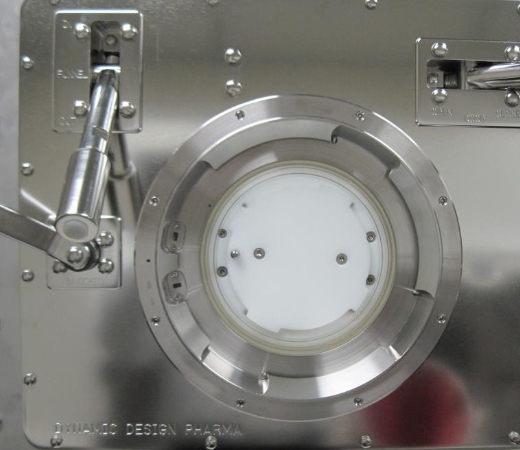

Photo Gallery

Related Products

The Alpha port that is operated from outside the isolator. No operator gloved entry into the isolator to perform the docking process.

The glove support system that optimizes VHP gas coverage. “Hand” that spreads the fingers of the glove to optimize VHP coverage.

The RTP Canister for the more challenging applications. With our patented NR Technology, the beta is free to rotate relative the canister body.