- Ideal for applications where adequate VHP gas distribution is difficult to achieve

- Mixing fans are inside the isolator during the VHP decontamination, not when your product is there

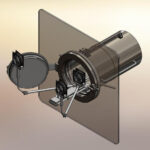

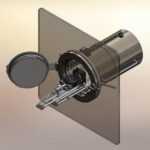

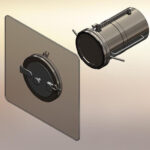

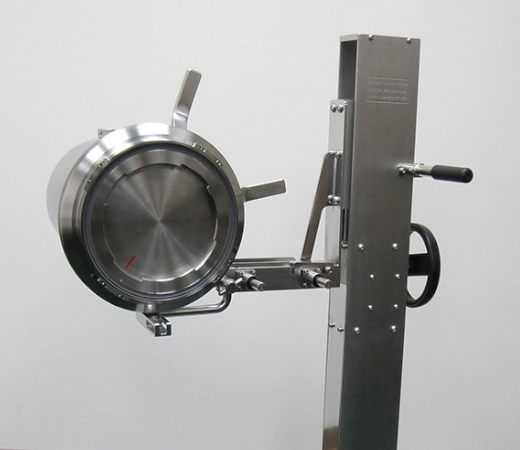

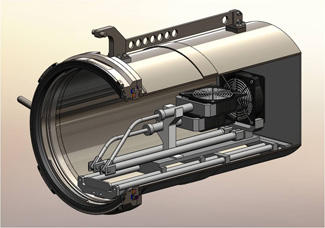

- The configurable air mixing assembly is housed within a dedicated NRC Canister

- Mechanical configuration assures repeatability to the validated fan position

- Easily customizable to the requirements of the application

Download Presentation

Download Presentation

System Description

A system that docks onto a standard RTP port of the barrier isolator for the purpose of creating air turbulence within the isolator chamber during Vapor Hydrogen Peroxide (VHP) decontamination.

The system consists of a Non-Rotating Canister (NRC) containing three fans that are extended out of the canister body and into the isolator chamber before starting the VHP cycle. The three fans are attached to a manually actuated shuttle that is housed inside the NRC. This method of attachment results in repeatable positioning and orientation between VHP cycles.

Two fans are mounted on individual swing arms that reach well into the isolator system. A third fan, hard mounted to the shuttle mechanism, creates air turbulence in front of and within the NRC thus assuring good VHP coverage of internal surfaces.

At the end of the VHP cycle, the fans are stowed back into the NRC by the operator through the isolator gloves. The design of the system is such that the stowing operation can be accomplished by touching surfaces that have been decontaminated by the VHP cycle.

Advantages

- The Air Mixing Module eliminates the need of permanently mounted air mixing fans inside the isolator system.

- Built on the NR Technology platform

- The system permits controlling the airflow direction during smoke studies and VHP cycle development.

Specifications

- Nominal RTP port size: 270mm and 350mm.

- Total number of fans: 3 (2 adjustable, 1 fixed).

- Electrical requirements: 115Vac 60hz or 220Vac 50Hz.

- Stowing of the fans after use can be achieved by touching surfaces that have been VHP decontaminated.

- Fan skid can be stowed by using glove manipulations only.

System Operation

Following are the steps to be followed to connect and oeprate the air mixing module:

- The Air Mixing Module is docked to the RTP port prior to the start of the VHP cycle

- The RTP door is opened to access the internal components of the NRC.

- The shuttle mechanism, with the fans attached, is pulled out of the NRC to the extended position.

- Both adjustable fans are raised to the upright position and moved over to the validated position. They are locked in position.

- Both adjustable fans are rotated on their mounting axis and locked into position.

- Fan #3 is fixed in position and therefore requires no operation.

- The electrical connection in the rear of the canister is made to a standard electrical outlet.

- The VHP cycle is performed.

- At the end of the cycle, the operator, via the isolator gloves, stows away the fans back inside the NRC and closes the RTP door.

- The NRC is undocked from the RTP port and taken away.

Documentation

The system includes an instruction manual containing the following sections:

- Instruction manual document:

- Installation, operation, programming and maintenance instructions

- Electrical and pneumatic diagrams

- Assembly drawings

- Spare parts list

- Validation support documents:

- System specification

- Functional/Design specification

- FAT protocol (executed)

- IOQ protocol

Photo Gallery

Related Products

The RTP Canister for the more challenging applications. With our patented NR Technology, the beta is free to rotate relative the canister body.

A multitude of clean room compatible solutions for the safe handling of beta canisters and feeder bowls.